Introduction to Beer Packaging

Packaging is a crucial stage in beer production, ensuring that the final product maintains its flavor, carbonation, and shelf life. Whether you are a small craft brewery or a large-scale production facility, selecting the right canning or bottling equipment is essential for efficiency, quality control, and product consistency.

In this article, we will explore the key considerations for choosing beer canning and bottling equipment and why Micet Craft’s solutions are the best choice for brewers looking to optimize their packaging process.

Key Considerations When Choosing Canning or Bottling Equipment

1. Production Volume and Scalability

Your packaging needs should align with your brewery’s production volume. A small craft brewery may need semi-automatic machines, while high-output facilities require fully automated systems.

Considerations:

- Current production capacity

- Future scalability

- Output speed requirements

2. Oxygen Reduction and Quality Control

Oxygen exposure during packaging can affect beer quality and reduce shelf life. High-quality equipment should minimize oxygen pickup to maintain freshness.

Features to Look For:

- Counter-pressure filling

- CO2 purging systems

- Double-seam technology for cans

3. Automation vs. Manual Operation

Automation levels vary from manual fillers to fully automated canning and bottling lines. The right choice depends on your budget, workforce, and production goals.

Types of Equipment:

- Manual fillers for small batches

- Semi-automatic systems for mid-sized breweries

- Fully automated lines for large-scale production

4. Bottle vs. Can Preference

Choosing between bottling and canning depends on your branding strategy, distribution channels, and consumer preferences.

Advantages of Bottling:

- Traditional aesthetic appeal

- Suitable for aging specialty beers

- Recyclable and reusable

Advantages of Canning:

- Lightweight and cost-effective

- Better light and oxygen protection

- Ideal for outdoor-friendly packaging

5. Sanitation and Cleaning Efficiency

Clean-in-place (CIP) systems ensure hygienic filling, reducing contamination risks and ensuring consistency across batches.

Important Features:

- CIP-compatible fillers

- Easy maintenance and cleaning options

- Integrated sanitation procedures

Recommended Canning and Bottling Equipment from Micet Craft

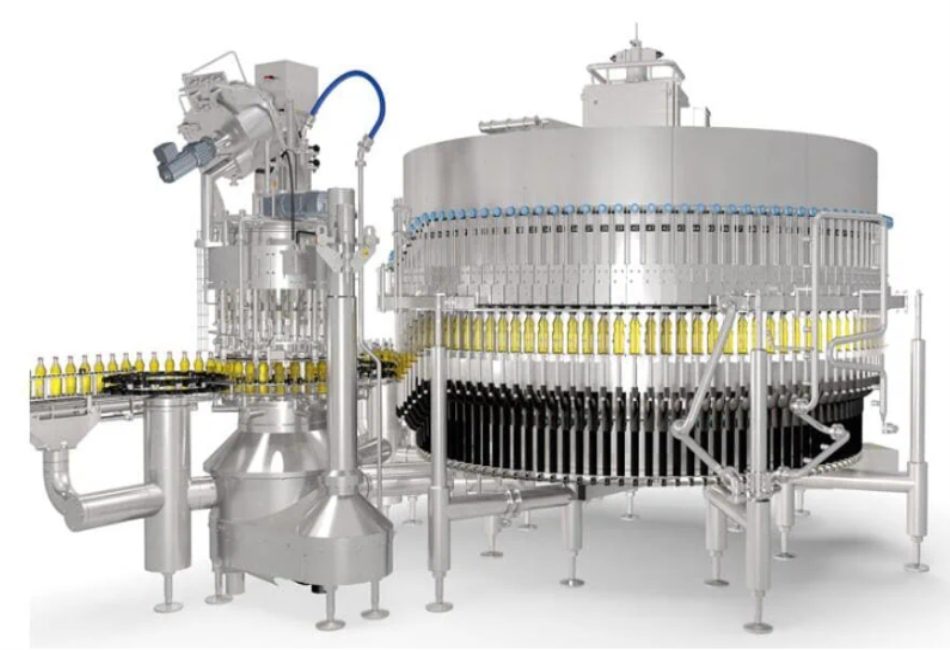

Micet Craft provides high-quality, innovative beer packaging solutions designed for breweries of all sizes. Here are some of their top recommendations:

1. Micet Craft Automated Canning Lines

Ideal for breweries seeking high-speed, efficient packaging with minimal oxygen exposure.

Features:

- Counter-pressure filling for precision carbonation

- CO2 purging for oxidation control

- High-speed automated operations

2. Micet Craft Semi-Automatic Bottling Systems

Perfect for mid-sized breweries that need flexibility and efficiency in bottling operations.

Features:

- Customizable bottle sizes

- Precision capping for a secure seal

- Integrated filling and cleaning systems

3. Micet Craft Compact Manual Fillers

Best for small breweries and limited production runs.

Features:

- User-friendly operation

- Low-cost investment

- Ideal for specialty and seasonal beer batches

4. Micet Craft High-Speed Kegging Solutions

For breweries looking to expand into draft beer distribution, Micet Craft’s kegging systems provide seamless filling with minimal product loss.

Features:

- Fast and efficient keg filling

- Oxygen reduction technology

- Compatible with various keg sizes

FAQs

1. Should I choose cans or bottles for my brewery?

The choice depends on your branding, target market, and distribution strategy. Cans are lightweight and protect beer from light exposure, while bottles offer a premium aesthetic for specialty brews.

2. What are the advantages of an automated packaging system?

Automation increases efficiency, reduces labor costs, ensures product consistency, and minimizes oxygen exposure, leading to longer shelf life and improved beer quality.

3. Why choose Micet Craft for packaging equipment?

Micet Craft offers durable, high-performance canning and bottling equipment tailored to different production needs. Their innovative technology ensures efficiency, scalability, and superior beer quality.

Selecting the right canning or bottling equipment is essential for any brewery aiming to maintain quality and efficiency. Whether you are looking for manual, semi-automatic, or fully automated systems, Micet Craft provides cutting-edge solutions that cater to breweries of all sizes. Investing in the right equipment will not only enhance your beer’s shelf life and presentation but also streamline your production process for long-term success.Moonkatt Taba Squishy Toys