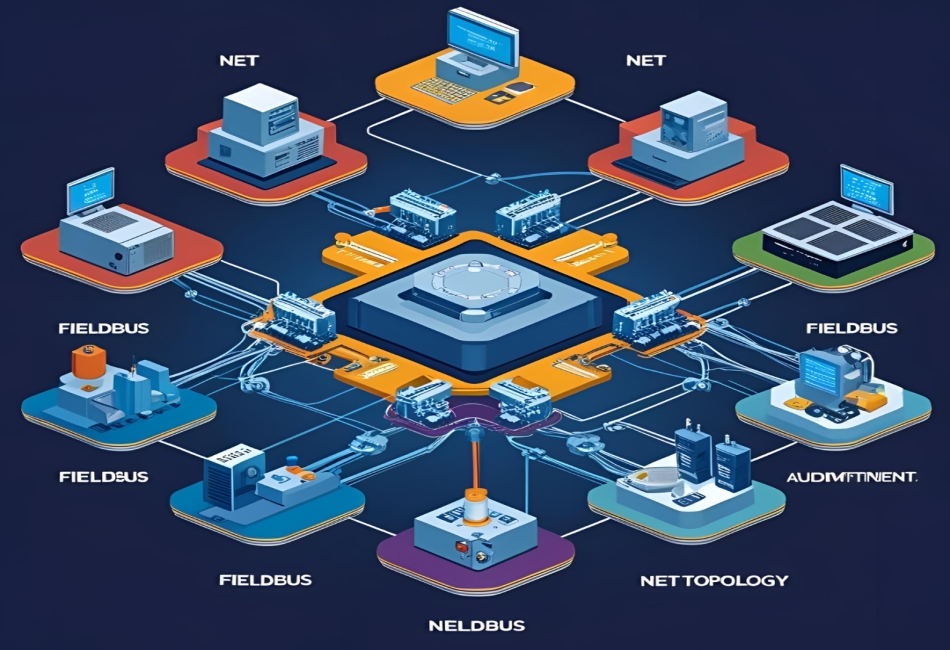

Due to limited device connectivity, RS232 serial communications slowly became backdated when Fieldbus came into the industrial sector. Fieldbus includes several computer networks that are used in industrial automation. These computer networks help in seamless input-output communication that does not require every device to be connected to a controller. In this regard, devices like Emerson AMS Trex Device Communicator are used in specific Fieldbus protocols to troubleshoot on-field issues in industrial applications. This post will help you identify the benefits and functions of Fieldbus in the field of industrial automation.

What is a Fieldbus in Industrial Automation?

It refers to a group of communication protocols that improve industrial automation. More specifically, this system is mainly used for transmitting data between control devices and the system. Therefore, the devices are enabled for real-time control, which helps in overall industrial monitoring.

What Are Some Common Fieldbus Protocols?

There are different Fieldbus protocols that vary depending on their utilization and the industries they are used in. Here are some common Fieldbus protocols.

- FOUNDATION Fieldbus

- Modbus

- ProfiBus

- HART

- ProfiNet

- EtherCAT

- DeviceNet

Determining the Fieldbus protocol is very crucial while designing industrial control. Moreover, not every Fieldbus protocol supports all communication modules. Plus, Fieldbus protocols are considered important in industrial automation because they help simplify wiring and enable a seamless connection between input and output devices. Different communication tools are compatible with different Fieldbus protocols. For example, Beckhoff EtherCAT Terminals are compatible with Fieldbus devices with Profibus, DeviceNet, and ProfiNet Fieldbus protocols. On the other hand, devices like Emerson AMS Trex Device Communicator are useful for both FOUNDATION and HART Fieldbus protocols.

What Are the Key Functions of a Fieldbus in Industrial Automation?

Acting as a replacement for a traditional point-to-point wiring system, Fieldbus uses a bus topology. Hence, it secures high-speed communication, which helps in exchanging data.

● Automotive Manufacturing

In Automotive manufacturing, Fieldbus technologies help in developing synchronization of thousands of devices. Therefore, it provides precise, accurate control and real-time monitoring when products are on the assembly line. For example, a terminal communicator like Beckhoff EtherCAT Terminals helps in the synchronization of different product lines.

● Petrochemical Industry

In the petrochemical sector, FOUNDATION FIELDBUS provides instrumental support encouraging safety and efficiency. Furthermore, it contributes to replacing the analog connection, reducing the wiring cost.

● Building Automation

Fieldbus systems in the building automation sector contribute to improved and faster data exchange between different on-field devices.

● Device Bus Network

The functionality of a Device Bus network is quite akin to Sensor bus networks, but it works on a larger operational scale. In this network system, every individual element can be controlled.

● Control Bus Network

In this control level, Programmable Logic Controllers (PLCs) and smart devices are connected. Thus, the complete control configuration is established by gaining control of every instrumental network.

● Enterprise Bus Network

It refers to a system where all computers and industrial devices are connected. This is the most complicated of all the Fieldbus networks and can be expensive depending on the industrial operation. In this network system, large-scale data collection is ensured with bulk data transfer and computerized monitoring.

Benefits of Fieldbus for Automation

The implementation of Fieldbus systems for industrial automation has brought many changes in communication. Here are some key benefits of using Fieldbus technology, which contributes to developing an improved industrial network.

● Reduced Wiring Requirements

A most crucial benefit of the Fieldbus system is minimized cabling requirements. The Fieldbus system is important in connecting hundreds of devices to a single connection point and controller. Therefore, the cable requirement is reduced vastly compared to other wiring systems. Moreover, the Fieldbus System also focuses on reducing the length of cables.

● Easier to Install

Fieldbus systems are much easier to install compared to parallel wiring. The entire process of installation and planning for a Fieldbus system requires less time.

● Minimized Cost

Implementing Fieldbus systems eliminates the requirement of connecting every individual device within a network or a controller. Therefore, the establishment cost and network running-up cost are reduced significantly.

● More Reliable in a Networking System

Since the Fieldbus systems use short signal paths, the trust for accuracy is increased. Moreover, Fieldbus systems also enable protection from interference, which happens during the analog systems.

Conclusion

In the field of industrial automation, Fieldbuses have been an effective communication control system depending on the application. Fieldbus uses communication terminals like Beckhoff EtherCAT Terminals to manage connections between multiple Fieldbus systems. Identifying the right Fieldbus requires dependence on the requirements of the application.